Architecture

'Value Engineering' 2023-Style Adds Real Value As It Cuts Cost

Value engineering needs a reset to satisfy both the business requirements to produce homes profitably in trickier times, and to win over customers whose discrimination and hesitation guards may go up at any moment.

David Akre, a principal at Whole Loan Capital, LLC, responds this way to the question, "what inning are we in?"

3rd inning.

Lots more demand out there. Builders are only making minor concessions. Their margins are solid.

The Fed will hold rates here, suppressing demand but not enough to hurt home prices.

One thing to come out of this will be more focus on building houses faster, cheaper, better.

The taut, crystal clear logic of Akre's view, and an airtight tie between his assertion – "3rd inning" – and its punchline conclusion, i.e. "faster, cheaper, better" houses, rings so true. Founder and former New Home Company ceo Larry Webb's take has an uncannily similar ring:

You have to manage your company like it is the 8th but buy land as if it the 4th."

Webb's guidance, "manage your company like it is the 8th" and Akre's dot-connection to how that might look and work in the real world – "faster, cheaper, better" homes that both price customers in and delight them – funnel focus on a strategic and operational bulwark of the moment "value engineering." The catch-all tactic currently crosses almost every homebuilding operating and enterprise leader's lips as a cut-to-the-chase navigational non-negotiable.

Market dynamics have brought the new residential construction and real estate businesses' two most treacherous shoals to navigate into a cold-light-of-day moment of reckoning:

- Relative affordability among households that are – or could be, or would be, or may not be – prospective new-home customers even as they're getting slammed by a double-whammy cost-of-living and higher-for-longer borrowing cost environment

- Relative sustainable profitability in a topsy-turvy business environment of sticky inflation, stubbornly high costs of capital, and uncertain homebuyer conviction and wherewithal

Most homebuilding operators have gotten the message that the days of being able to pass along added costs to buyers – at least for many of them – are numbered or over. In fact, in many markets they're having to find ways – i.e. value engineer – their home products both to stabilize pricing and, where necessary, bring asking prices lower to meet the market and keep their order pace at a feed-the-machine level.

Reports started flowing during the summer that builders had begun doing what they do when risks that their prices, products, and locations may show signs of decoupling from willing and financially able-buyer pools.

- Single-Family Home Size Moves Lower to More than a Decade Low – Eye On Housing

- The answer to rising home prices: smaller homes – Theweek.com

- Higher Costs Pushed Builders Toward Smaller, Attached Homes – Zillow

- Goodbye Bathtub and Living Room. America’s Homes Are Shrinking – Wall Street Journal

America's homebuilding business community is nothing if not highly-skilled and deeply experienced with how value engineering works. If it ever were only about subtracting square footage, aesthetic details and finishes, lot sizes, and other direct-costs, they would not be around today to tackle present-day customer and business challenges.

David Akre's conclusion fits right here:

One thing to come out of this will be more focus on building houses faster, cheaper, better."

In that context here's a thought-piece it would do well under the particular set of conditions and drivers to check out. It starts this way:

We have all heard the phrase “Better, Faster, Cheaper, you can have any 2” but is that actually true? … Yes, of course, that’s true, but we are going to talk about it anyways because this is really a conversation about quantity and quality … which is ultimately a conversation about value. Welcome to episode 69 “Better Faster Cheaper” – Bob Borson, Life Of An Architect

When many homebuilders we've known talk of value engineering, they're lens – understandably – focuses mostly on the "engineering" aspects of the tactic, i.e. the "faster and cheaper" parts of the whole equation.

Naturally, that may leave customers in a bind, given that they may well be motivated – even highly motivated – to own a new home. A new home that's not "better" may be something, but, especially in this day and age, most customers of any commodity or service or solution don't demand just something, they demand better.

So, builders are into the engineering, and their ever-more-demanding customers – even given their life-stage needs, preferences, etc. for "something vs. nothing" – insist on better.

In a sense, then, value engineering in the mid-2020s then, needs a reset to satisfy both the business requirements to produce homes profitably in more turbulent and tricky times, and to win over customers whose discrimination and hesitation guards may go up at any moment.

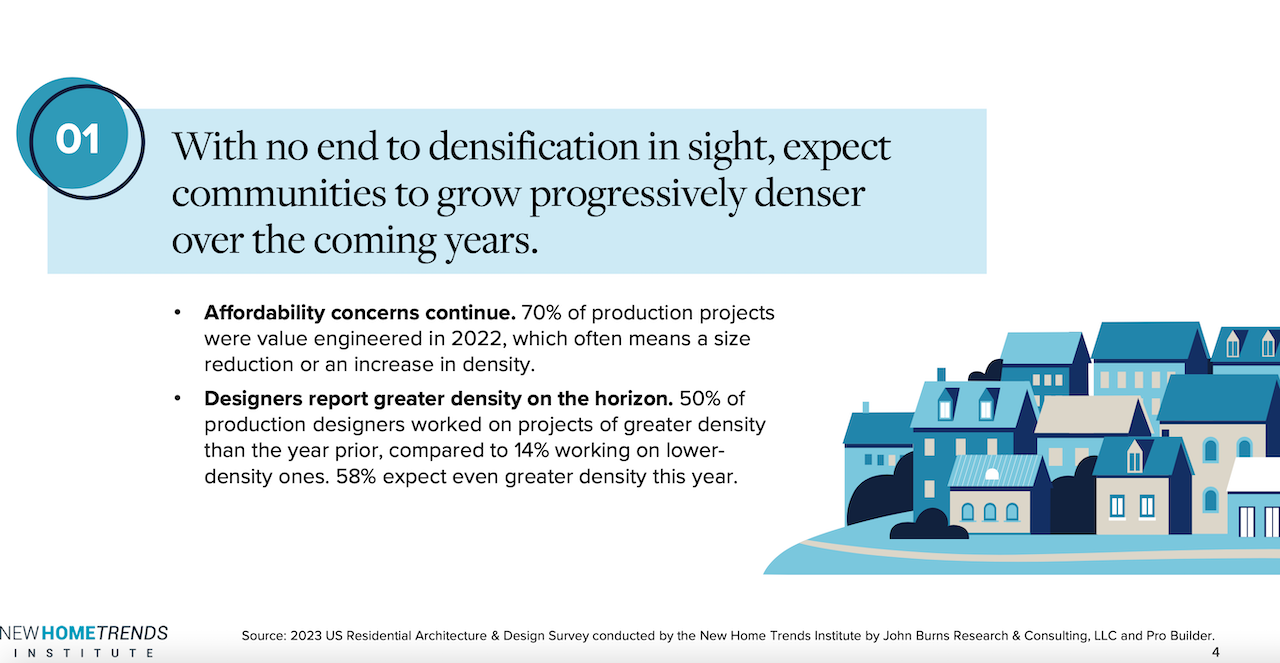

The team at John Burns Research and Consulting's New Home Trends Institute touched on the need to develop a "not-your-father's-value-engineering" approach in a Spring Report, with highlighted insights like these.

- With no end to densification in sight, expect communities to grow denser over the coming year.

- Homes will shrink, but not all spaces will lose square footage equally

- Main-level living spaces will grow by cannibalizing formal living and dining spaces

- There will be a shift in outdoor living space from the upper levels to the ground floor

- Primary suite size will remain the same, forcing reductions from secondary bedrooms and lofts

- Designers predict the future of starter homes will be high-density attached or build-to-rent

The market has seen the early-wave iterations of these ideas already showing up in new communities, but we anticipate buyer demand preferences and behaviors will pressure architects, construction leaders, and business strategists to continue their teamwork to refine and revise their products to hit the "better" mark even as they achieve the "faster and cheaper" operational and direct input expense levels they're shooting for.

When we interviewed Tri Pointe Homes division president Ken Krivanec recently, he struck the nail on its head on the very balance we're talking about:

When you get into a market correction, everybody talks about value engineering," says Krivanec. "I like to think of it as value enhancement. You use all of that data you get. Every time a customer comes in, they're telling you what's really important to them and what they're willing to invest in. We're trying to make value enhancement part of the original design and so it doesn't require some event to get value engineering back out of the house as opposed to the consumer is ultimately going to tell us what level of value they want."

This idea of starting blank-sheet-of-paper style, to design and build what consumers will value – exclusive of anything they don't value as much – inverts the more typical approach to value engineering, which takes a home and subtracts from its size, finishes, and specifications to arrive at a lower-cost product.

We talked recently with a team of f0lks suited to this challenge (i.e. opportunity) to hear from them how they strive to accomplish the dual mission of being "better" for the customer and "cheaper and faster" for the builder. They include, Larry Simon, VP-project management at Tri Pointe Homes, Tracy Sexton-Hall, VP-marketing, Tri Pointe/Pardee, Ken Niemerski, Senior Principal, Bassenian Lagoni, and Michael Stone, VP-senior designer, Bassenian Lagoni.

Here's how they look at what's at stake in, as Ken Krivanec describes it, "value enhancement," or as we might, "re-value engineering" to drive more benefit in both directions:

On Making A Home Design Stand Out

Larry Simon, Tri Pointe Homes

What value engineering meant for many years in our previous lives was that we'd develop product that ended up being cookie cutter. Some builders, I would say, are more driven towards that by the purchasing department and price points. At Tri Pointe, we definitely don't start out with a price point and say, 'put these five things together' and develop your product. We're more focused on the final end-user customer product. Meaning, 'how are we getting real bedrooms that work? Do we get a great room experience that's at a level buyers expect at our price points?' So we're trying to value engineer the the footprint of the house, the elevation and the style how it's going to look. So I think a lot of builders go in with the idea of 'we need to use these windows and we need to use this size door and we have to have this ceiling height and plate."

A year ago I was building two stories, and now we have a model park full of single stories. So our ability is to adapt to those changes by adapting price points, adjusting elevations or certain materials. Once a footprint is in the ground, you can design a box is the most efficient. However, we tend to not design boxes because we know what's what our competitors do. Everybody builds a car with four wheels. We want to build it with four cool wheels, and maybe that all four wheels turn or all four wheels drive so that people can see that difference and pay us for that."

Listening to the buyer

Traci Sexton-Hall, Tri Pointe Homes

We view ourselves as a premium builder, so when we look at a particular parcel of land, we're looking at the demographics of the people that are going to be purchasing that particular home, whether it's in a planned community, or in our infill projects just outside of a planned community. We have to look at how can we can still deliver that premium level home, but maybe a little bit more affordable, especially in our townhome product. We're never going to be one who's going to compete with homebuilders that are the lowest price-point. We want to make sure that our homes have that premium feel because they have those valued things that our customer that our home buyers are looking for, built into the home at, you know, an affordable price for the demographic.

We work to make each plan take that extra step, for example in our application of color schemes that allow it to be a little different for each elevation exterior. The paint still gonna cost the same. The application is still going to cost the same but when you drive through the neighborhood, it really helps to differentiate and makes us feel definitely more premium. Not all of the homes around you look exactly the same as your home. That's just one of the key things that helps to set us apart – when you look down the street you're seeing the color schemes that make us stand out."

Value Engineering's Dual Benefit

Ken Niemerksi, Bassenian Lagoni

Value engineering is challenging to us because that typically happens after the process. And you've designed homes for whatever product segment you're working on, and whatever location it is, and then you realize, 'oh gosh, we are $10 a square foot over. We need to cut costs. We need to make it know, doable. The pro forma isn't working. More times than not, in that value engineering meeting you're just getting rid of detailing. You're getting rid of the stuff that really makes it nice and appealing to potential homebuyers.

So we've really had to take a look at doing things differently. When we sit down, it's important that all stakeholders are involved in those early meetings, people who really have the knowledge and the resources available to them to tell you if you're going in the right direction or not. When you've got that collaborative team environment, working on starting a project, knowing what that end goal is, that's important.

An example of that is we typically will get a lot size to start working with. Let's say it's a 50 by 100-foot lot size. Based on that lot size, they've got a square footage in mind, and based on that square footage, in the back of builders' minds, they're already thinking: 'Here's what we can probably build the house for and here's how much we can sell it for.'

However, when you start laying out that house and you're dealing with setbacks and design criteria that may be local or specific to that community, you realize that you're limited with your square-foot footprint. You realize you don't have the square footage needed for that ultimate sale price.

Recently we were working on a project and we said, 'wait a minute, let's look at a bigger lot size and bigger square footage for the house. Are you able to get more for that larger square footage, because now your buyer profiles a little bit different?'

In a program we're working with, the higher square footage made it work. Penciling out for builder and adding value for that buyer profile and that cost per square foot. That's something that we just typically haven't done in the past.

Another example involves working with setbacks. There are minimum setbacks that we deal with that we get from the planning group, whoever that might be – city or county or even design guidelines – and you try to work within those. But there may be some other things that are important to that buyer profile, or that builder that we're working with. Pools, for example. You can work with your minimum rear yard setbacks, you can design that that house to accommodate that setback in the rear so they can have a pool. Now, that square footage that you've got may be a little less, however, there's a higher potential for that homebuyer with that square footage because they know that now they can get a pool in that rear yard, which they'll value more."

Beyond First Cost To Lifetime Value

Michael Stone, Bassenian Lagoni

It starts with the upfront planning piece and understanding where you're going to. If we have that target program, we're designing to value. The value engineering is designed into the plan at the very beginnin, and then you don't really have value engineering at the end. You're targeted with it.

We do a design charrette process with all the stakeholders in the room. Key people there are purchasing and construction managers. It's not the upfront design people. It's knowing what's that added cost gonna be and whether you can pull off that that 20 foot span and the great room or needs to be 18 ft. Those are the things that change the base house upfront and if you know you can only do an 18 foot expand based on whatever requirements you have, you can design the room to that versus having to come back and retool the whole thing as you're going through construction documents.

If we're fixed on having that 20-foot span that was already designed, you can't take it out, because then you're taking stone and siding off the front of the house. You're already down the road.

Another thing that gets overlooked is the factor of a construction module, the two-foot or four-foot grid scenario for construction materials. Eliminating extra waste in construction materials during construction is always a factor and value that gets overlooked down the road. But if you consider that upfront in your design, and you tell your trades, that also helps reduce the cost and they're not including this waste factor to their baseline. It's little moves like that don't seem like a big deal. But when you start incorporating them at the very front in the planning and design stages, they reduce that value engineering aspect and then they become incorporated in the plan like they were intentional. So you're driving that value down in the cost of the house, and the value.

It's What's Upfront That Counts

Ken Niemerksi, Bassenian Lagoni

In value engineering meetings in the past, you spent time in the middle of the process saying, 'I need to add a chase here. I need to move this wall or move this window,' all on-site course corrections that added cost. Now if we're thinking about that on the front-end, you don't need to worry about that on the back-end and we don't necessarily have to have a structural engineer with us at the very beginning. If the people in that meeting have that knowledge and that experience and have worked together, those things happen naturally and flow together. So your design response solution, there's a value added to that square footage that you're providing and designing into the project itself right from the start."

MORE IN Architecture

Beyond Blueprints: AI Alters Home Design, Development Calculus

In an exclusive one-on-one, Higharc co-founder and Special Projects leader Michael Bergin reveals how AI is eliminating homebuilding bottlenecks, cutting soft-cycle time, and transforming home design from an unpredictable process into a precise, real-time system.

Building Back L.A.: Fast-Track Permits That Build In Resiliency

Demand to build homes with materials that can withstand the increasingly frequent and intense wildfires is growing. However, whether the permitting process can keep pace with the demand has become an increasingly-contested, and urgent issue.

2025: A Turning Point For Homebuilding Tech Integration

This year marks a pivotal shift as homebuilders adopt unified digital solutions that connect design, ERP, and CRM systems into a single lifecycle platform. This strategy enhances builder efficiency, cuts complexity, and drives faster product delivery through integration and AI-driven tools.