Technology

Here's A Robot That Solves For Prefab Wall Panel Spray Foam Insulation

Spray-R, a spin off from Chemovator, provides the solution which repeatably, safely, and swiftly applies spray foam insulation in offsite panel facility environments.

What makes your average builder recoil from a word like "innovation" can make that same builder do backflips when he or she strikes upon a solution.

It might easily be that that builder is looking at one and the same thing. One term makes them queasy and suspicious, and the other – if the outcome clearly backs up the claim – excites both confidence and joy. Constitutionally, builders like to solve problems rather than to go on a treasure hunt.

It's practically an unwritten rule, "if it ain't broke [more than it's already broken], don't fix it."

Solutions in the complex and complicated process by which 18,000 components get assembled into a 2,200 square-foot house must pass a sniff-test that's pretty simple to understand, but pretty hard to do. They've got to do at least one or more of the following.

- Cost less, and potentially, impact selling price of a home

- Simplify a process to produce less need for skilled time and proficiency at equal or greater quality in the outcome

- Improve the performance value along measures of consumer-demanded durability and structure, energy use, health and comfort

- Protect workplace safety and health in installation and assembly

Nested within those four non-negotiables come solutions to building's Big 3 challenges of the current half-century:

- Relative affordability – as a direct function of household wages

- Sustainability – as a measure of impact on energy use and carbon emissions

- Capability – Technology- and data-augmented human skills

Call that "innovation" and, immediately, reflexively, the BS-meters start dialing up. Skeptical builders imagine increased costs, or impacts to the predictability of their current processes, or some other unintended consequence likely to come back to bite them later.

On the other hand, they'll listen to a solution, one that doesn't make more problems than it solves for and either lowers the barriers to improving efficiency or raises their own ability to give end-user homebuyers more value that they'll pay for.

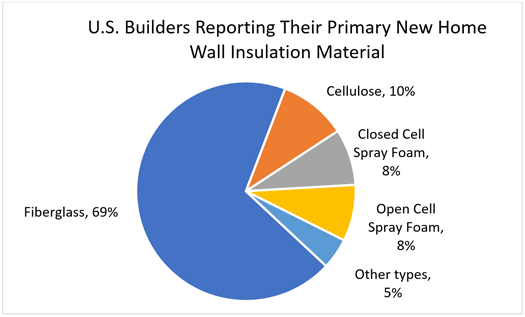

Which is the gist of Spray-R, the heart of which is a robot-applied closed-cell spray foam to wall panels insulation at the touch of a button.. Designed, coded, and engineered for offsite, modular, and prefabrication facilities, the knowns of closed-cell spray foam insulation benefits are clear – accounting for a 16% marketshare among U.S. homebuilders, and its 5.6% CAGR trajectory in global market growth. These known benefits include indoor air quality improvement thanks to a better air and vapor barrier, high R-value for energy performance, and structural enhancement.

Double-digit current market shares for both offsite and panelized construction spray foam insulation equate to enormous business and operational opportunity for an industry known to be ripe for disruption, but hesitant about embracing it.

Almost all homebuilders tend to acknowledge – and lose sleep over – a premonition that a pivot to 21st Century technology that profoundly augments human efforts in home and community development and construction is likely in the next decade. But unless the cost barriers to foray into this future state of housing construction come down, they're loathe to participate as guinea pigs in what stands to be a bumpy and iffy transition period.

The Spray-R process, which as co-founder Lisa Render notes in a conversation with The Builder's Daily, can occur in many existing offsite and panelization facilities with room at the "end of their production line." Directionally, integrating an essential step in the construction process via an automated, financially efficient, precise, fast, and human-free mode checks all the boxes of potential disruption to Rube Goldberg-style complexity in current start-to-completion vertical construction workstreams.

Spray-R is about enabling safe indoor spraying. It is the robot that sprays, while the operator supervises the process from outside the cell.”

“The process is automated, safe, precise, and fast. A picture of every single panel is taken before and after spraying, fully documenting the insulation process. This is all included as part of spray foam-as-a-service.

The Spray-R team – which incubated its plan under Chemovator – has expertise in construction including building codes, chemical processing, architecture, robotics, as well as cloud and machine learning. The founding team consists of Tomasz Cwik, leading the company; Lisa Render, responsible for customer success; and Erik Metz, who oversees the technology development and operations.

This is about helping offsite and modular prefabricators provide more value to their customer," Render says.

But, shhhh! Let's not go so far as to use the I-word, because that might scare people off. Instead, talk about Spray-R as a practical, money-mitigating, labor-scarcity solving, performance-enhancing, and process-simplifying solution. Then, builders might be all ears.