Technology

Beyond The Walls, Part 3, Scaling A Capability Culture

This is Part 3 of a three-part inside story of Diamond Age, one of new residential construction’s most promising technology-powered start-ups, whose goal is to alter the homeownership affordability crisis in the next decade.

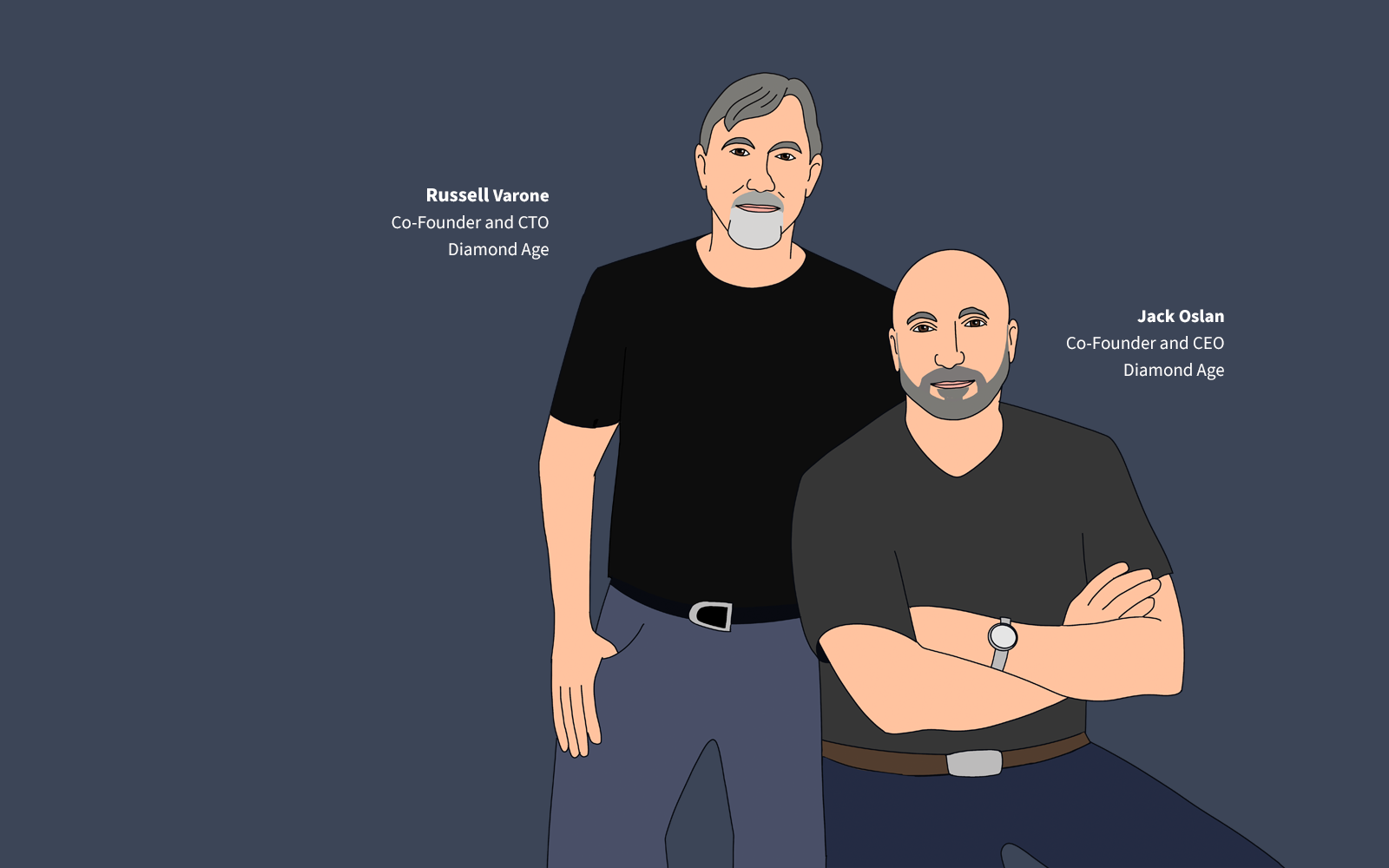

[Editor's Note: This is Part 3 of our three-part inside story of one of new residential construction’s most promising technology-powered start-ups, which aims to impact the homeownership affordability crisis in the next decade. Diamond Age co-founders Jack Oslan and Russell Varone invited us to visit the three-year-old, mid-stage firm’s Phoenix headquarters as well as its first two real-world project sites with Century Communities’ Century Complete line of homes, about half-way between Phoenix and Tucson, AZ. We’ve borrowed one of co-founder Russell Varone’s oft-used expectations-management rules of innovation development – “crawl, walk, run” – to structure our report. Part 1, “Crawl,” published in TBD on Jan. 19, here. Part 2, “Walk” is here. Part 3, "Run," looks specifically at the role of a human capital culture of capability at Diamond Age, and how that factors into the firm's plan to scale.]

Software, Hardware, Capital, People

Diamond Age co-founder Jack Oslan's vision is for more people with more livelihoods in America making places for people to live, not fewer. But he and co-founder Russell Varone are working like the devil to roboticize at least 26 different processes in new-home fabrication onsite, as a fully-vertically integrated manufacturing facility. They'd subtract as much as 55% of the "labor" input costs – costs that match up with construction process tasks frontline workers typically do on today's home building job sites.

(You know, the ones that struggle even today to tap into a reliable, predictably-priced pool of subcontractors to progress home construction build-cycles with efficiency and quality.)

To understand how these two concepts do not collide – robotics and automation vs. more people in more building jobs – and cancel one another out, it takes a mental pivot. The mindset change requires grasping something basic about the term building science. The term can be a bit of a mischaracterization, or at least a gross understatement.

At a high level, building science really amounts to a mashup of all or most of the branches of physical science – physics, chemistry, biology, materials, etc. Its scope includes both the process of fabrication and assembly of a home and the performance qualities of the structure and systems that make a building, plus their impact on the environment.

That's not to mention computer sciences, data, machine learning, software development and robotics. Of source, too, there's the Dismal Science – economics – and for those who expect to sustain a livelihood putting this super STEM stack of rigors to work, leadership, management, marketing, finance, operations, and the psychological sciences of motivation, inspiration, collaboration, and striving.

The idea is simple. Capability to build the estimated 2 million to 5 million new homes the U.S. has underbuilt over the past 10 years – plus those millions more necessary to keep pace through the next decade – and to do it at a dramatically lower expense means two things. One, is that modern manufacturing is not optional. Two, is that hugely greater volumes of output – even with manufacturing capability – mean more payroll positions for people in building livelihoods, not fewer.

Nine ways to Sunday, building science – in its modern manufacturing context – is a dynamic mesh of hardware, software, capital, and people. When she took the job as chief technology officer at Volumetric Building Companies just over one year ago, Helena Lidelöw described this dynamic fabric this way:

When the first step you take is to stop looking at what we're doing as this venture as construction, and start looking at it as manufacturing, the tasks, and challenges, and opportunities open up and look differently," Lidelöw says. "The world I come from is one that takes things systematically, and it's led to thinking of manufacturing as a science that requires data, and systems, and people from separate expertise and knowledge areas – sales, design, factory engineering, purchasing, and the rest – levering together for the outcomes. For each knowledge, expertise, and financial interest area, the data needs to clarify the value gain precisely so that we can optimize the output."

An early 2023 day at Diamond Age – a mid-stage construction technology start-up whose single purpose is to produce homes that cost much less to build so that homebuilders and developers can charge less for people to own or rent them – provides an early-evolution view of what Lidelöw's talking about, this "levering together" of software, hardware, money, and people.

From Crawling To Walking

For Diamond Age's co-founders Jack Oslan and Russell Varone to accomplish what they've set about doing – to produce new homes at a step-change lower cost – the work they and their teams in a shop in Phoenix and out on a job site 70 miles away amounts to learning to walk. Producing homes in 60 days today – as Diamond Age is doing at Century Communities' Mountain View Estates in Casa Grande, AZ – will drop days, labor, and carrying costs to the bottom line. We wrote:

Against, the 180-day cycle lower end comparison, Diamond Age – even with just 10 of its eventual full-platform of 26 factory-in-the-field robotic and automation tools deployed – is on pace to net a pick-up of 3,720 build-cycle days for the 43-home project.

When in the next 12 months all 26 of the planned robotic tools are deployed and a couple more of the gantry systems make their way to the job sites, each gantry array equipped with its own platoon of technicians, system operators, tool-changers, local finishing trades, site supervisors, telemetry analysts, etc., a micro-version of Diamond Age's whole factory-in-the-field operating model will take its full shape. Then, averages of 60-days – slab to hand-off of the keys to a new owner – look more like 30 days or less.

When we talk about vertically-integrating the process, it's about looking at all the repetitive, heavy-lifting, often-dangerous aspects of home assembly, and developing robotics tools to perform those processes," Oslan says. "It suggests, as well, working with materials and building products suppliers within that vertical-integration mindset. Is there any reason roofing material couldn't come in one huge roll of roofing tiles that a robot could simply unfurl over the underlayment with the flashing already in place?"

At that point, by the end of 2023, a 43-home project for Century Complete models in the Mountain View Estates pivots to a run-rate of 1,290 days, versus a typical stick-built run-rate of 7,740 days of build-cycle time. That then drops 6,450 days to a bottom line of efficiency, productivity, margin protection ... and the opportunity to sell more homes profitably for a lower cost.

Running, Scale, And A Capability Culture

Getting from just learning to walk – where Diamond Age is now – to running is a human capital learning and discovery lab in itself, one that crushes the 75-mile distance between the Casa Grande job site and the Phoenix shop, with a constant feedback loop of scanning, measuring, data capture, analysis that course-corrects or codifies based on what works in which environmental conditions as the robots run through their paces.

In the hardware-software-people nexus these days at Diamond Age, a 20-hour-a-day swirl of young people like Spencer work to fuse new technology capabilities to the messy world of dirt, local zoning, and capital flows. Spencer showed up one day, accompanying a software engineer friend of his who was applying for one of Diamond Age's shop positions. At the time, Spencer worked as an engineer at a tech company known to everybody not living under a rock. He'd mentioned he was interested in what Diamond Age was doing.

Spencer is a true free spirit," says Oslan. "He took a week off from his other job, and, as a job interview with Diamond Age, he spent the week vacation in our shop creating a prototype for one of our robotic tools. He presented the prototype and then went back to his job and gave notice he was leaving. Now, Spencer's living in his Sprinter van in our shop's parking lot because when he's not working, he's out rock-climbing and hiking. The amenities in the building – shower, kitchen, etc. – provide Spencer the living basics that support his free spirit lifestyle and provides a super-talented engineer for Diamond Age. We even built a climbing wall in the parking lot, and he and his friends here have contests when they need a break."

Then there is César. César is a robotics systems operator who sits in a trailer flanking one of the new home sites. During construction, he's got eyes on the gantry system and its 3D printing tools, and like an air traffic controller, three oversized computer monitor screens, each with a set of color-coded dashboards that "intermediate" the tools with the outside environment.

César reflects – in Diamond Age's, Jack Oslan's, and Russell Varone's minds -- the kind of person in the kind of jobs the future of homebuilding will produce far more of as it walks into its future.

Cesar came to us because we needed help in the shop lifting heavy stuff," says Varone. "His background and experience was as a warehouse worker, and initially, he was helping us move bags of sakrete as we were figuring out our concrete mix to do the pilot house up in Silicon Valley in 2021. He went head-down, put in long hours, started learning about the rheology and the viscosity of the mixes that would pump under pressure through our 3D-printer die. When we moved the operation to Phoenix last year, he came to us and said he was ready for an opportunity to train and do more."

Oslan and Varone well with pride, not just in having proved that a vertically-integrated factory-in-the-field model – even at 45% of its eventual tech suite – can both work and produce profound, potentially game-changing cost-saving impact they propose as a value proposition to today's homebuilding and residential development enterprises.

What comes through as energizing for both of them – whose own arcs of career achievement in applied technology attest to a bootstraps, under-credentialed overachiever style – is the evolving culture they see coming together at Diamond Age.

When we hire you to work at Diamond Age," Oslan says. "We do it with the understanding that you will do more than our job description can articulate, because we're learning every day what it takes to fully realize this 'first principle' quest of building more affordably."

At scale, in a sprint-filled five years, Oslan and Varone envision a national hub-and-spoke style capability network, set up in a hardware-software-people-capital system not unlike military regiments, platoons, etc. And the fact is, armed services veterans – Air Force, Marine, Army, and Special Forces – are already part of the human capital talent pool that have helped Diamond Age get up and walk on its own as a fledgling, financially-rational "super-sub."

We've got people like Jake and Josh out on our job sites working to connect our robotics tools, the software, and the environment on a minute-by-minute basis," says Varone. "They served together on the same aircraft carrier with a nuclear payload. Do they have a Stanford, Berkeley, MIT degree? No. What they do have is a rigor about precision, collaboration, and adaptation to changing conditions. They know how to solve hard problems."

Echoes Oslan:

Whether it's out there at the site, or here in the shop where our teams are building and evolving models that will power our ability to batch out each piece of this process in a way that will drive value today to our builder customers, and evolve into our factory-in-the-field capability, the culture here is so laser-focused on our goal, to make entry-level housing more attainable."

Every minute of everyday, they're climbing that wall.

MORE IN Technology

Lennar Taps Into Geothermal To Power New Colorado Homes

A major homebuilder's bet on geothermal heating and cooling for over 1,500 new Colorado homes could pave the way for mainstream adoption as buyers increasingly seek sustainable, energy-saving features.

AI Crushes Missing-Middle Time And Cost Curves Toward Affordability

Developing multifamily rental and for-sale properties takes time — sometimes years -- depending on a labyrinth of zoning rules and the whims of local jurisdictions.

Brandon Elliott’s Next Big Thing: An Uber-Style Building Trades Platform

After selling Elliott Homes to Meritage, the Gulfport, Miss.-based entrepreneur sets his sights on transforming trades with a logistics-tech startup that aims to make construction faster, smarter, and more affordable—starting with siding.